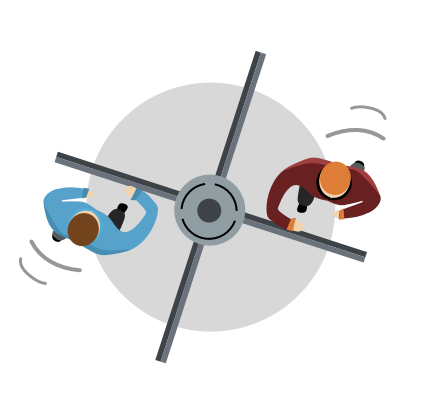

Unique elevator turning system!

Elevator Protection System

Our easy-to-build-yourself Elevator Protection Systems makes it possible to let several people use your elevator at the same time. The turning system (tourniquet) allows people to get in and out on any floor!

Read MoreMore people safe in the Elevator

With all the different movements in a commercial building, the elevator is currently a logistical nightmare. In many cases, the maximum number of people (or families) is only 1, which limits the number of elevator movements. Our system protects against droplet viruses more effectively.

If this is compared to using e.g. a stairwell, the risk of our system is much lower. After all, in a staircase to the 4th or higher floor, the chance of spreading due to perspiration, cough and / or sneeze drops is greater. Our system creates an additional barrier against the current Covid-19 virus.

Easy do-it-yourself building blocks

Our system is designed so that everyone can put it together. The basic parts are packed in such a way that the modular system can be assembled and disassembled in sequence. The round base provides stability,

the pole is slid into the base and the screens can be easily hooked into the pole. As a final step, the top cross-shaped part is placed to prevent the vibrations of the screens. An instructional film shows how this works.

Minimal touch

The Elevator Protection System has been developed in such a way that it rotates easily. With the arrival of the Covid-19 virus, everyone has become aware of the risks of spreading viruses. In addition to the known sneezing and coughing, skin touch is also a risk.

The reason for developing our system in such a way that a rotation can be started with the hip, elbow or shoulder. In this way, the employee’s discipline and our solution achieve an optimal protection point in the elevator. Also see our demo movie how this works!

More people safe in the Elevator

With all the different movements in a commercial building, the elevator is currently a logistical nightmare. In many cases, the maximum number of people (or families) is only 1, which limits the number of elevator movements. Our system protects against droplet viruses more effectively.

If this is compared to using e.g. a stairwell, the risk of our system is much lower. After all, in a staircase to the 4th or higher floor, the chance of spreading due to perspiration, cough and / or sneeze drops is greater. Our system creates an additional barrier against the current Covid-19 virus.

Easy do-it-yourself building blocks

Our system is designed so that everyone can put it together. The basic parts are packed in such a way that the modular system can be assembled and disassembled in sequence. The round base provides stability,

the pole is slid into the base and the screens can be easily hooked into the pole. As a final step, the top cross-shaped part is placed to prevent the vibrations of the screens. An instructional film shows how this works.

Minimal touch

The Elevator Protection System has been developed in such a way that it rotates easily. With the arrival of the Covid-19 virus, everyone has become aware of the risks of spreading viruses. In addition to the known sneezing and coughing, skin touch is also a risk.

The reason for developing our system in such a way that a rotation can be started with the hip, elbow or shoulder. In this way, the employee’s discipline and our solution achieve an optimal protection point in the elevator. Also see our demo movie how this works!

Prevention against virus droplets

Supporting the discipline of people with means and instructions today is very relevant. Our solution is therefore just supportive and not a replacement. Our solution provides an additional barrier against the spread of virus drops that arise when coughing, sneezing or perspiring.

Everyone must continue to follow the rules and codes of conduct of governments health institutes and the company!

Go to your workplace…

In our conversations with potential customers, we collected information about the time required to get all employees to their workplace. In one of the largest office buildings in Groningen, a logistics elevator plan starts at 7:30 am and the last person arrives at his / her workplace at 11:30 am.

With our solution, this can be reduced to 1 hour or less (depending on the number of people getting off per floor). In addition, the movements to meeting rooms and company restaurants will also optimize.

Go to your workplace…

In our conversations with potential customers, we collected information about the time required to get all employees to their workplace. In one of the largest office buildings in Groningen, a logistics elevator plan starts at 7:30 am and the last person arrives at his / her workplace at 11:30 am.

With our solution, this can be reduced to 1 hour or less (depending on the number of people getting off per floor). In addition, the movements to meeting rooms and company restaurants will also optimize.

Our Elevator Protection Systems

LPS-3 Turn module for 3 persons

€ 2.799

LPS-4 Turn module for 4 persons

€ 2.999

LPS-M Turn module (Custom build)

Quote

LPS-T Screen module for 2 persons

€ 540